Union Tray® Laser Spot Technology makes it more affordable

Laser Spot Technology makes Union Tray® accessible.

Uniron Tray® is a product of UPT’s “Etching + Diffusion Bonding Technology”.

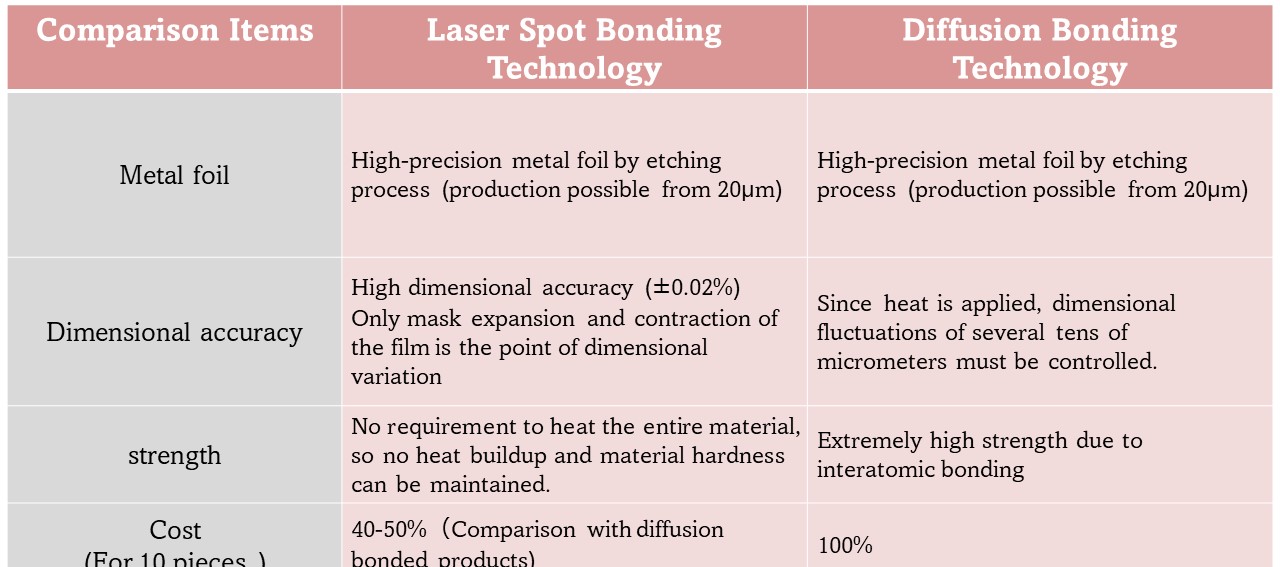

Diffusion bonding is a method of atomic bonding in which metal foils are laminated and pressurized under high temperatures to create an atomic bond that boasts unparalleled strength.

So, it is the most suitable method for jigs and trays that require high durability.

On the other hand, diffusion bonding technology can be a time-consuming manufacturing process, and a bit more expensive. Today, we would like to introduce you to a low-cost version of the Union Tray® that uses laser spot technology.

While maintaining the features of the Union Tray®, such as dimensional accuracy and mass production effectiveness, which cannot be achieved with conventional machining technology, the durability of the Union Tray® is lower than that of diffusion bonding technology, but it can be provided at a very reasonable price.

This is the best solution for customers who cannot achieve satisfactory processing accuracy with machine/cutting technology and find diffusion bonding technology a bit expensive.

Challenges in

Diffusion Bonding Technology

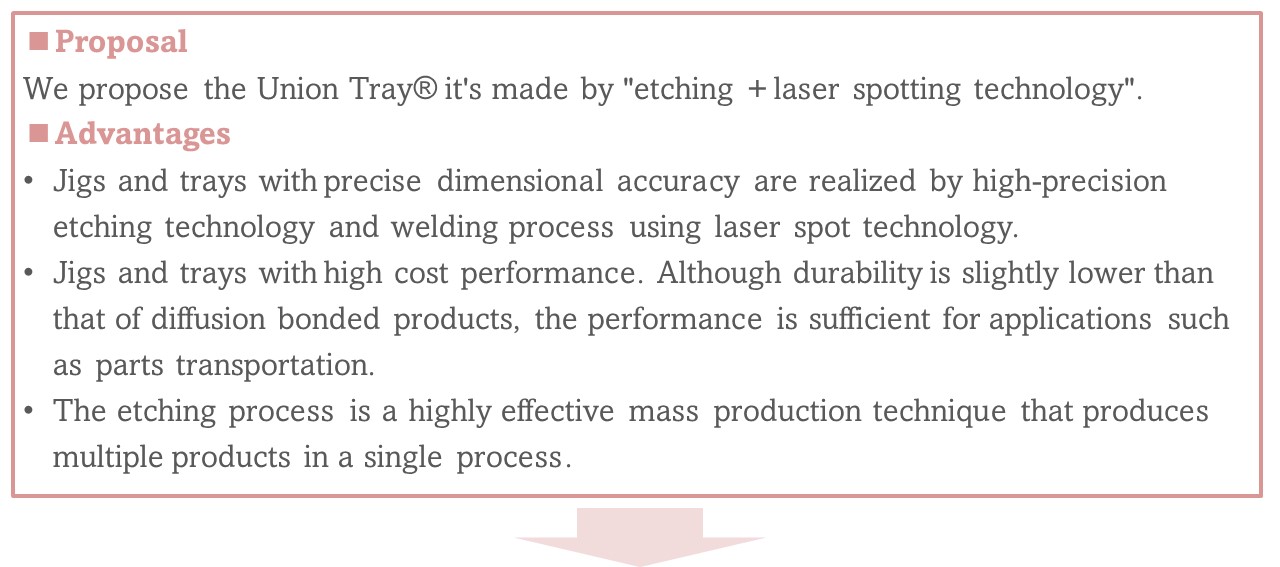

Proposal

Case Study: Union Tray® for Electronic Components

Value 1

Value 2

">

">